Address: 58/1E, Tien Lan 1 Hamlet, Ba Diem Commune, Hoc Mon District, Ho Chi Minh City

Website: www.ecospeed.vn

EcoSpeed Vietnam Co., Ltd. was established in 2017 and is a company that transfers steel butt welding technology products from Japan. Steel butt welding technology products have another name, EcoSpeed welding technology, used in steel joining in civil construction and road and bridge construction.

With the technical support and cooperation of the leading Japanese company group – the group of companies that invented and applied EcoSpeed welding technology in Japan, we believe that we will accurately transfer technology, ensure Japanese quality construction and contribute to the development of Vietnam’s infrastructure as a supporting industry.

We are also currently cooperating with the Japan Steel Welding Contractors Association to provide technical guidance to students participating in the steel welding specialty program.

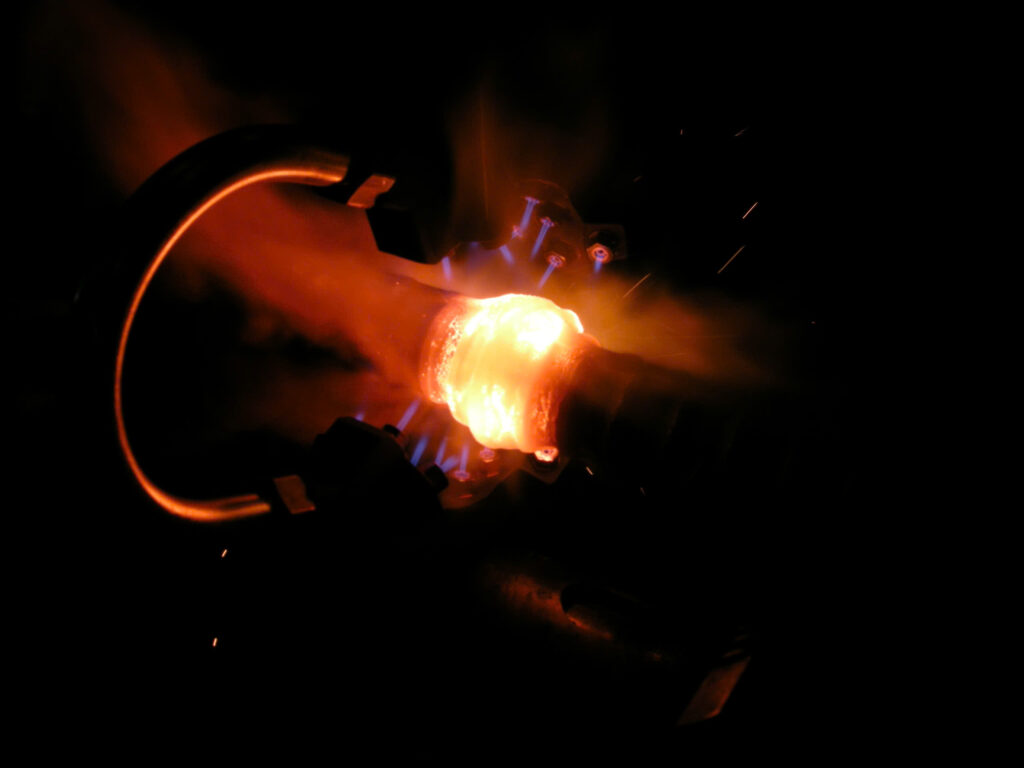

Butt welding technology – EcoSpeed welding technology

This is a pressure gas welding technology, using a mixture of combustible gas (Compressed Natural Gas CNG and Oxygen) to heat the two ends of the steel bar, while using PS Ring (reinforced steel end cap) to prevent surface oxidation during the heating process, and using mechanical pressure to press the two ends of the steel bar together. The two ends of the steel bar are connected together by a metal bond, helping to ensure good quality of the weld. Currently, this technology has been widely used in high-rise building and bridge construction projects throughout the provinces and cities in Japan.

The butt welding of steel joints has been proposed by the Ministry of Construction, and the Ministry of Science and Technology has agreed to publish the standard TCVN 11977:2017 “Concrete reinforcement steel – Testing methods and acceptance criteria for welding joints using pressurized gas”.

Advantages of EcoSpeed welding technology compared to other traditional steel joining methods

– The steel bars are connected together by metal joints, without using third materials to connect, so it brings more safety, solidity and quality. Two steel bars are welded concentrically so they act as one continuous bar.

– Save construction costs compared to traditional overlapping methods by at least 20% depending on project scale and for steel diameters from D18 and up.

– Saving concrete reinforcement steel materials, saving the amount of reinforcement steel loss during construction.Reduced steel density at the joint, no blockage when pouring concrete.

– Improve workers’ skills and awareness. Improve the construction process to become more scientific.

– Can be applied to locations where other methods are difficult to apply.

Satisfy the technical specifications of concrete reinforcement steel such as: Yield limit, tensile strength limit according to the regulations of ribbed steel in standard TCVN 1651-2:2008: “Concrete reinforcement steel – Part two. Ribbed steel”.

Disadvantages of EcoSpeed welding technology:

Limit construction in heavy rain and strong winds

Initial equipment investment costs are high.

Workers need to be trained before construction

en

en  vi

vi zh

zh